110 TWh of waste heat potential in France, with one-third coming from the food industry (source: ADEME).

According to the International Energy Agency (IEA), around 50% of global energy consumption is lost as waste heat, primarily from industrial processes and electricity production (IEA, 2023).

40% target for reducing greenhouse gas emissions by 2030 compared to 1990 levels (SNBC)

2050, carbon neutrality target (France 2030)

Up to 50% of the fossil energy consumed by a boiler for steam production is used solely to maintain the network at the corresponding temperature and pressure, often well above the process requirements.

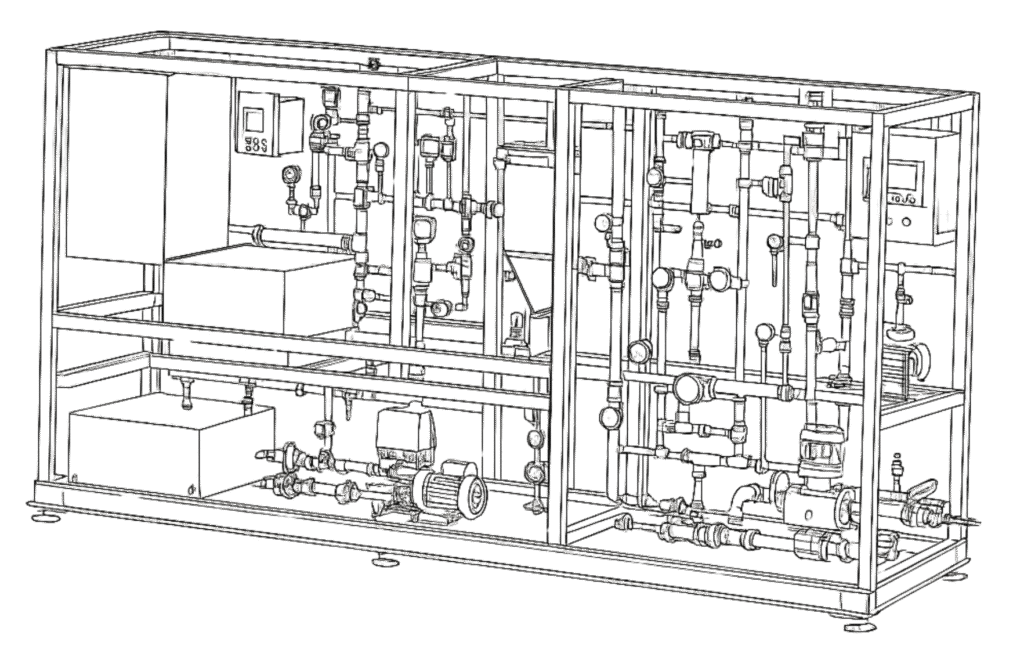

ECOFICIENT® is a 100% electric industrial solution, with a COP of 3–5, capable of heating and cooling processes from 6°C to 120°C (standard version). It is a needs-based system, avoiding the oversizing common in conventional equipment.

· Core Features: Energy loop, patented energy storage, independent thermal fluid production for continuous or batch processes.

· Target Sectors: Food, cosmetic, pharmaceutical, and other industrial applications.

The ECOFICIENT® solution ensures the production of thermal fluids precisely as needed, just-in-time, and at the expected temperature gradients. Our targets are production units consuming heat and cold in the agri-food, cosmetics, pharmaceutical, and other industrial sectors. The ability to independently produce each thermal fluid allows for continuous needs as well as batch applications, thanks to adapted storage volumes.

100%

electric

0

fossil fuel

100%

energy savings (up to)

Identify waste heat sources, particularly from cooling, and map hot and cold energy consumers.

Assess energy and utility consumption to identify performance levers.

Evaluate project relevance for Energy Savings Certificates (ESC) or other support mechanisms.

Complete technical description including equipment power requirements and integration with on-site installations.

Compilation of expected gains, performance commitments, and ROI calculation.

CAPEX or OPEX options, including third-party investment possibilities.

Validation of values and performance on our industrial pilot.

Based on actual heating and cooling demands, define the ECOFICIENT® solution’s specifications by determining the power ratings of the units and the characteristics and volumes of the various energy storage systems, including their operating temperatures.

Detailed design with execution plans and bills of materials for launching manufacturing, procurement, components, and subcontracting.

Monitoring of manufacturing and execution to ensure schedule adherence and quality standards.

Factory Acceptance Test (FAT) and technical documentation validation.

Supervision of the installation and execution of all required connections.

Site Acceptance Test (SAT) to confirm performance, user training, and support prior to handover.

Maintenance contracts.

Subscription-based equipment monitoring, preventive maintenance, improvement recommendations, and performance indicators.

• Energy loop: Waste heat recovery and utilization from cooling.

• Intelligent energy storage for precise thermal management.

• ROI (Return on Investment):

Up to ≤ 3 years without incentives

Up to ≤ 1 year (with ESC/other schemes

• Reliability: Proven, robust technologies and expert partners.

• Performance: Improved profitability, productivity, and environmental impact; supporting energy transition via energy efficiency and decarbonization.

• Long-Term Support: Integrated monitoring for performance supervision, preventive actions, and continuous improvement.

Power: 10 kW to 5 MW.

Temperature: 4°C to 120°C.

Temperature: 4°C to 120°C.

COP: 3–5.

Mechanical Vapor Compression (MVC) for >120°C.

Alternative heat transfer fluids for <4°C (e.g., glycol water).

Natural refrigerants: CO₂ R744, NH₃ R717, R290 propane, R600a isobutane.

Data access and monitoring subscription.

Cogeneration, renewable integration (PV, biomass, hydro, wind), and custom design.

ESC Certificates: IND-UT-102, IND-UT-113, IND-UT-114, IND-UT-115, IND-UT-116, IND-UT-121, IND-UT-131, IND-UT-132, IND-UT-136, IND-UT-137, IND-UT-139, RES-CH-108.

ADEME: Project calls, Heat Fund, R&D programs.

Water Agency: Financial incentives for efficient water management.

France 2030: R&D support for green tech and energy innovation.

EU Directive 2012/27/EU: Energy efficiency and industrial waste heat recovery.